RNA Manufacture

Biocell-developed RapidNA™ is a kit-free and scalable RNA manufacturing platform to produce custom-made high-quality RNA

The success of mRNA-based Covid-19 vaccines has propelled RNA-based products into the limelight. The technology behind these products is rapidly evolving and lends itself to a number of applications such as those in cancer immunotherapies, supplementation therapies, personalized medicines and primary industries. Production of high-quality mRNA is critical to the successful delivery of these applications. Most research institutes working on RNA-based applications use commercially available kits for the production of mRNA. This kit- based production of mRNA is neither scalable nor reproducible, thereby limiting the ability of these mRNA-based products to move into toxicology studies, clinical studies and commercial manufacture.

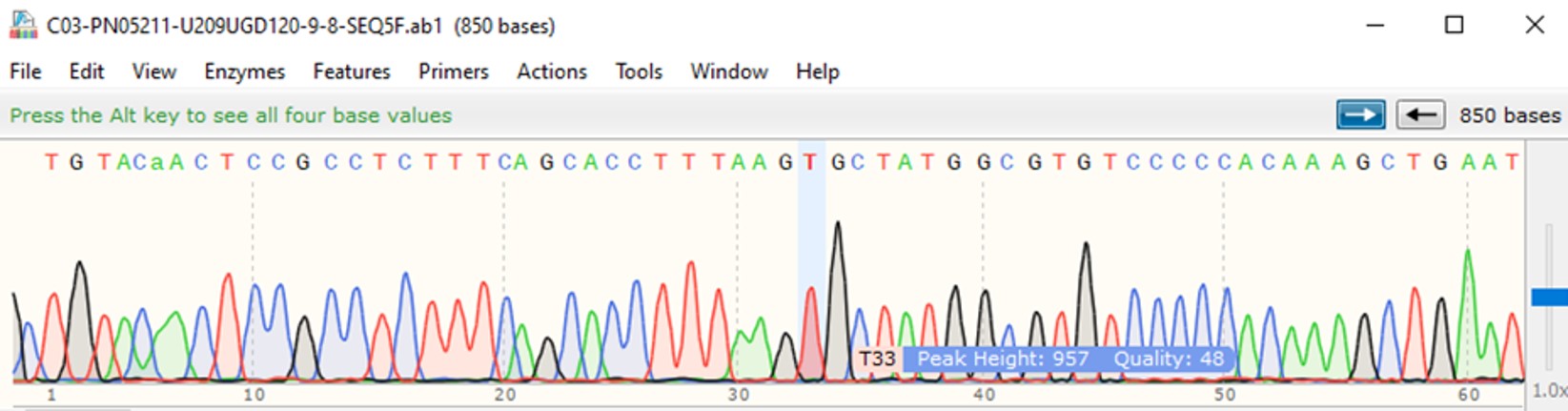

Biocell has developed RapidNA™, a kit-free, rapid, scalable, and optimized proprietary RNA production platform, at its state-of-the-art facility. The in vitro transcribed product is produced using validated equipment and certified high-quality reagents. Extreme care is taken to keep the process RNase-free and DNase-free. RapidNA™ can produce high quality mRNA at microgram to gram scale from variable lengths of DNA sequence.

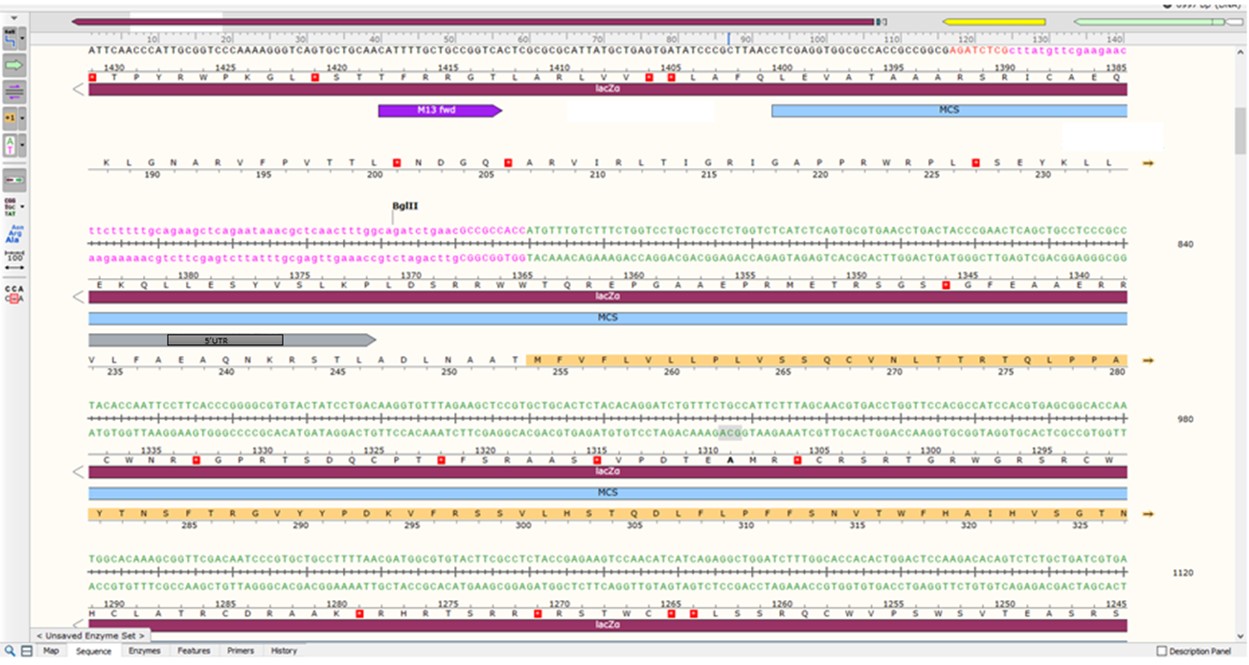

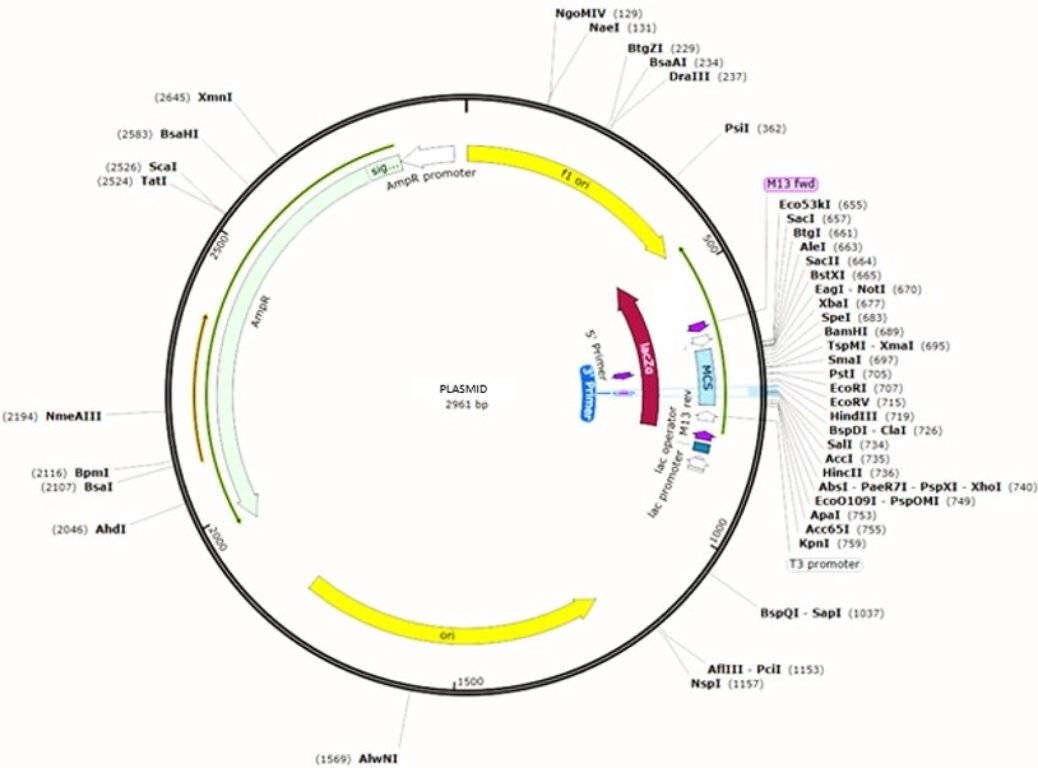

The DNA sequence of the development candidate ( DC) is optimized for its translation usage and then tailored to add a 5’ UTR, 3’ UTR, and Poly A tail to enhance its stability. The DNA sequence is also engineered to accommodate a capping structure if required, for either co-transcriptional or enzymatic capping. The embellished DNA is then embedded in a vector (pDNA) for transcription. The RapidNA™ platform precisely generates copies of mRNA from the pDNA template.

The RapidNA™ platform has optimized parameters that are necessary to enhance stability and reduce in situ degradation while maximizing yields.

RapidNA™ produces multi-fold increases in in vitro transcribed mRNA copies when compared to the leading In Vitro Transcription (IVT) kits. This platform is scalable as your project progresses through the development pathway, from preclinical to market-ready production. Biocell has a dedicated GMP-compliant facility with a state-of-the-art-fill and finish capability that can also support commercial-scale production.

Provide us with the DNA sequence of your development candidate (DC) along with your scale requirement and our plug-and-play platform can rapidly consolidate your DC into pDNA to produce mRNA in an integrated process.

We have partnered with leading global suppliers and technology pioneers who have assisted us through the RapidNA™ development journey. This proprietary platform is optimized for early development phase through to commercial production and would generate data and actionable insights for your mRNA program.

The RapidNA™ platform development was kindly supported by Callaghan Innovation, New Zealand Government’s Innovation agency.

Contact us to initiate your custom-built mRNA project at enquiries@biocellcorp.co.nz.